Soft Sono vs AKU COMP

Recently REC Indovent have received a lot of questions if soft flexible silencer with biocidal treated channel would be a better than traditional rigid flexible silencer and the original AKU COMP. Many of these sales argument and claims are both incorrect and misleading.

Since it still leads to a lot of questions, we hereby want to clarify the concepts and correct the question marks.

First: The basic rules for biocides in a circular economy.

The realization that we do not have infinite resources will require that more products can be recycled in the future. Biocides severely or completely limit the possibility of reusing the biocide contaminated raw material as another raw material for all future generations.

According to the Construction Products Regulation, all companies that place a product on the market are ultimately responsible for the product through the “cradle-to-grave system” and then there are supplementary Company rules for biocidal products.

- Always limit the use of and exposure to biocides.

- Never contaminate clean raw materials. Use recycled raw materials first.

- Biocidal contaminated plastic must not be recycled.

- Use biocidal products when no other solutions are available.

- Seek professional advice to find out your responsibility before buying, selling or installing and using a biocidal product.

- In accordance with the BPR (Building Product Regulation), The status of the biocidal active substances, and in particular approving entity with the approval date of the approved active substances must show in the documentation.

- Ensure that the applicable documentation and labeling of the product is correct.

- Read and strictly follow the recommendations on the packaging regarding installation, handling and circularity.

1. Antibacterial or Biocidal treatment

The soft channel with green inner channel is made of biocidal treated PP or PE fiber fabric. PP/PE fabric is treated with biocides because this is a cheap low-cost material that, due to its structure, is also a favorable place for mildew, bacteria and viruses to multiply on. The purpose of biocides is to kill and counteract this.

AKUCOMP rigid inner channel is very stable and durable. It has no biocidal treatment and is made of pure recycled and recyclable perforated aluminum sheet. It also does not need to be treated with any biocides because this surface is naturally unfavorable for the reproduction of bacteria and viruses.

2. Sound attenuation

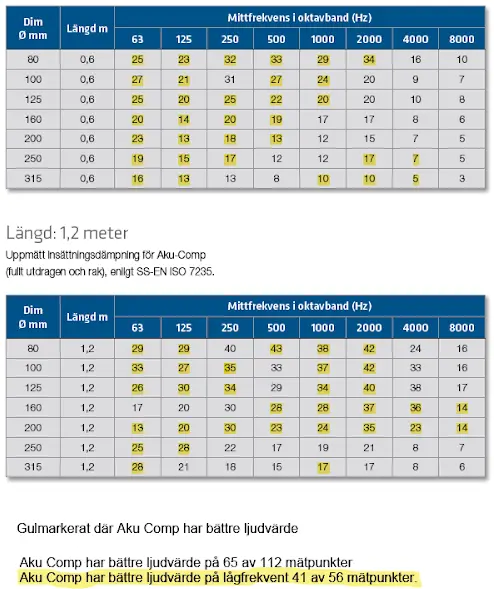

AKUCOMP has better noise reduction. When comparing the sound data, AKUCOMP from has better sound attenuation in 65 out of 112 measurement points (58% of the measurement points) in all dimensions 80-315 and frequency band 63-8000 Hz. As flexible silencers are especially good in the low-frequency bands (63-500 Hz), we have also compared these bands.

Then AkuComp has better sound attenuation in 41 out of 56 measurement points. So, a full 73% of the cases.

Bending the Flexible silencer 90° degrees:

Since the sound data is reported for a straight fully extended version, it can also be interesting to compare a 90° degree bent silencer, because it is more common with a bent than a straight situation when installing a flexible silencer.

In a lab test, the following can be established. AKUCOMP attenuates approx. 4 dBA better at a 90° position, while the green/soft channel attenuates approx. 2.5 dBA worse at a 90°degree bend.

The noise reduction difference is thus even greater in AKUCOMP:s favor with a 90°degree bend silencer.

Control measurement – Total sound attenuation SP dBA

| Rigid AKU COMP | Straight 1200 mm | 100 | 25 | 31,1 dBA |

| Rigid AKU COMP | 90° | 100 | 25 | 35,2 dBA |

| SOFT SONO | Straight 1100 mm | 100 | 25 | 29,8 dBA |

| SOFT SONO | 90° | 100 | 25 | 27,3 dBA |

3. Pressure drop:

Soft green channel has 3-4 times as high pressure drop as rigid AKUCOMP.

Pressuredrop measurements at the same flow and dimension and fully extended silencer

SOFT SONO 125 mm, 1,1 m

| 25 l/s | 4,9 Pa | Straight | 10 Pa | Bent 90° | 3,0 times more than AKU COMP |

| 30 l/s | 6,7 Pa | Straight | 14 Pa | Bent 90° | 3,3 times more than AKU COMP |

| 35 l/s | 8,9 Pa | Straight | 19,5 Pa | Bent 90° | 3,9 times more than AKU COMP |

AKU COMP 125 mm, 1,2 m

| 25 l/s | 2,4 Pa | Straight | 3,3 Pa | Bent 90° |

| 30 l/s | 2,9 Pa | Straight | 4,2 Pa | Bent 90° |

| 35 l/s | 3,5 Pa | Straight | 5,1 Pa | Bent 90° |

Attention:

Increased pressuredrop results in

- Increased energy consumption,

- Increased sound level

- Required air flow is not achieved

A typical example: with an air flow of 126 m3/h and connecting 2 green soft channel dampers bent at a 90° angle to the heat exchanger, a loss of 4.4 Euros will be incurred per year due to increased pressure losses (electricity consumption 0.25 EUR/kWh), and in 10 years, a loss of 44 Euros will be incurred.

If we connect 4 dampers, then the losses will be twice as high.

4. Air tightness:

The green soft channel has air tightness class C at 400 Pa

AKUCOMP has tightness class D. (D is higher tightness class than C)

When using class C products, air leakage through them can be up to 3 times greater than in class D products.

5. Fire resistant:

The general advice for ventilation systems and materials in air handling units has always been to choose the product/material with the highest fire rating.

The soft green channel does not have any labels, so documents are hard to find, maybe fire class is stated in their documentation?

AKUCOMP Alu has the highest fire class A1.

6. Cleaning of silencers

Many have seen pictures of how much dust can be collected in a sheet metal duct and in a polypropylene duct there is a risk that even more dust will collect.

A polypropylene duct with biocides will not be able to be cleaned traditionally. What happens to the biocides during cleaning? Can the biocides be destroyed? What safety equipment is required? A polypropylene duct clearly requires new routines, and you should make sure that a cleaning manual and the right tools are available when it is time to clean.

If needed - the dealer is obliged to be able to pass on clear instructions for cleaning and destruction.

The inner surface of AKU COMP dampers can be easily cleaned using the brushes on the duct cleaning equipment.

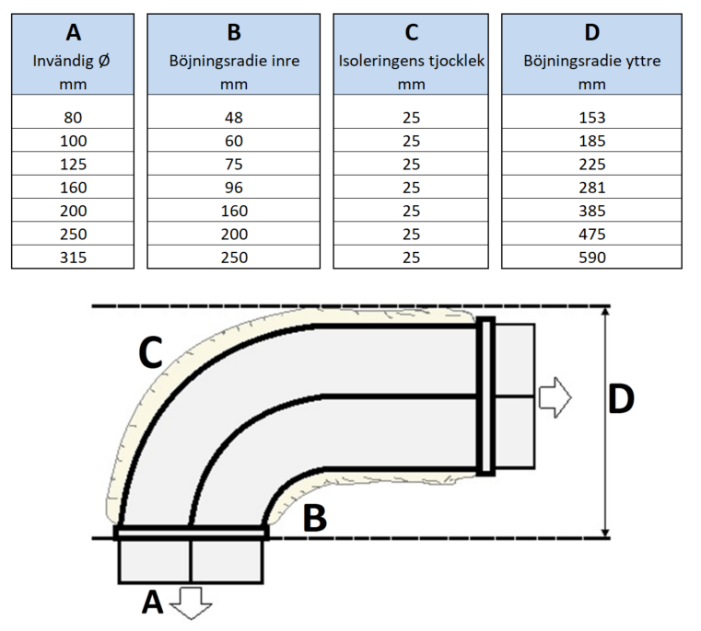

7.Bend radius/ Building height

AKUCOMP is equipped with sleeves that are 40 mm, while the soft green channel has sleeves that are approx. 70 mm. This means that AKUCOMP has a clearly smaller bending radius with a maintained airflow volume.

8. Conclusion of the study

Although new offers are appearing on the market, such as "Soft Sono" with biocides, the original "AKU COMP" aluminum silencers stand out with essential advantages: better sound attenuation (especially when bent), significantly lower pressure losses (which saves energy), and higher classes for airtightness (Class D) and fire resistance (Class A1). Furthermore, "AKU COMP" are easily cleaned with standard tools and, most importantly, they do not use biocides, which raise questions regarding health impacts and recycling possibilities.

You can find our "AKU COMP" products here: AKU-COMP and AKU-COMP Alu