Flexible vs. Galvanized Ducts: A Comprehensive Guide for Your Home Ventilation System

When building or renovating a home, the ventilation system (heat recovery) is one of the most critical engineering components for ensuring a healthy microclimate and the longevity of the building. However, once you have chosen the heat recovery unit itself, a second, equally important question arises: which duct system should you choose?

For many years, galvanized steel (Spiro) ducts dominated the market. However, in the last decade, a revolution has taken place in the residential sector with the emergence of flexible plastic duct systems. In this article, we will examine the differences, advantages, and disadvantages of both systems in detail so you can make the best decision for your home.

The Traditional System: Galvanized (Spiro) Ducts

Galvanized ducts are a classic solution that remains indispensable in industrial facilities, shopping centers, or office buildings where large airflows and large-diameter pipes are required.

Operating Principle

This is known as a "trunk" or "branch" system. A single large main pipe runs from the heat recovery unit, with smaller pipes branching off to individual rooms.

Main Challenges in Residential Premises

- Acoustics (Crosstalk Effect): Since all rooms are connected by a single duct network, sound travels easily from one room to another (e.g., a conversation in the living room can be heard in the bedroom). To avoid this, expensive and space-consuming silencers must be installed at every branch.

- Ceiling Height: Galvanized ducts have large diameters (usually 100mm, 125mm, or 160mm). Adding the necessary insulation layer and mounting elements often requires lowering the ceiling by 20–30 cm, which is a significant loss in modern apartments.

- Complex Balancing: To ensure enough air reaches the furthest room, the system must be carefully balanced using dampers. If adjusted incorrectly, these dampers can generate additional noise (whistling).

The Modern Standard: Flexible Duct System (e.g., REC Flex)

Flexible systems designed specifically for residential homes, such as the REC Flex System, solve many of the problems associated with older systems.

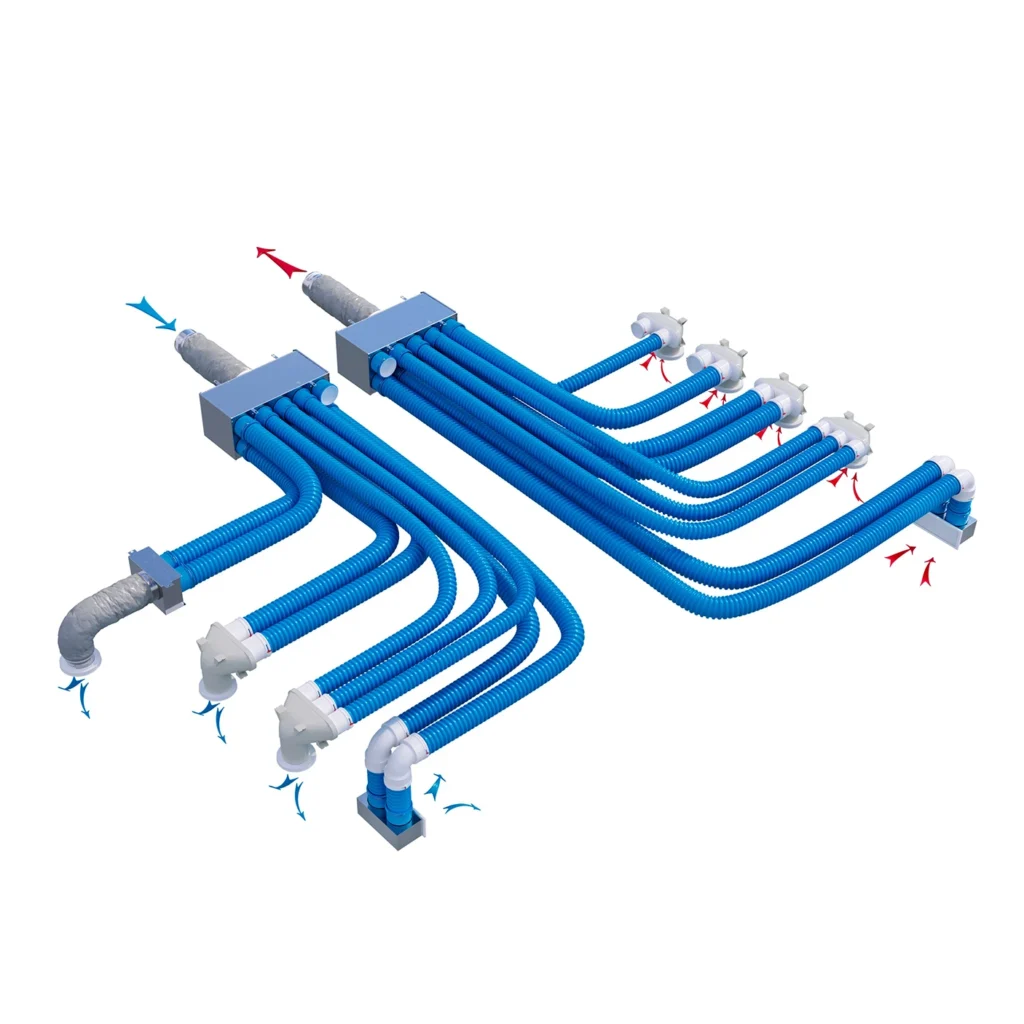

Operating Principle: Manifold (Radial) System

This is the fundamental difference. The system operates on a "star" or radial principle. Air flows from the heat recovery unit into a sound-insulated distribution box (manifold), and from there, a separate, continuous flexible duct runs to each room. There are no tees or connections between rooms.

Why Choose a Flexible System for Your Home?

1. Impeccable Sound Insulation

Due to the manifold system design, sound cannot travel from one room to another because the ducts do not connect directly. Furthermore, the ducts are corrugated on the outside but smooth on the inside, and distribution boxes often feature internal sound insulation. The result is a quiet ventilation system without the need for additional silencers.

2. Maximized Ceiling Height

Flexible ducts (e.g., REC Flex HDPEA) are only 75 mm or 90 mm in diameter. They are extremely robust (withstanding concrete pressure), allowing them to be:

- Concealed in minimally lowered ceilings;

- Installed within the floor construction (screed);

- Hidden inside timber frame walls.

3. Superior Hygiene and Easy Maintenance

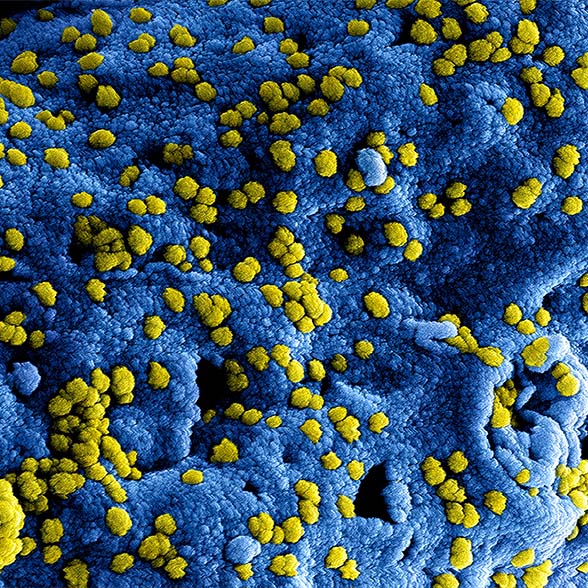

Metal ducts accumulate static charge, causing dust to stick to their walls. Over time, dirt can accumulate in corners and joints. In contrast, high-quality flexible ducts are made from virgin polyethylene (HDPE) with antistatic and antibacterial properties.

The antistatic surface prevents dust accumulation, while the antibacterial coating (often using silver ions) prevents the growth of microbes and mold. Additionally, cleaning a continuous flexible duct with no sharp corners is much easier.

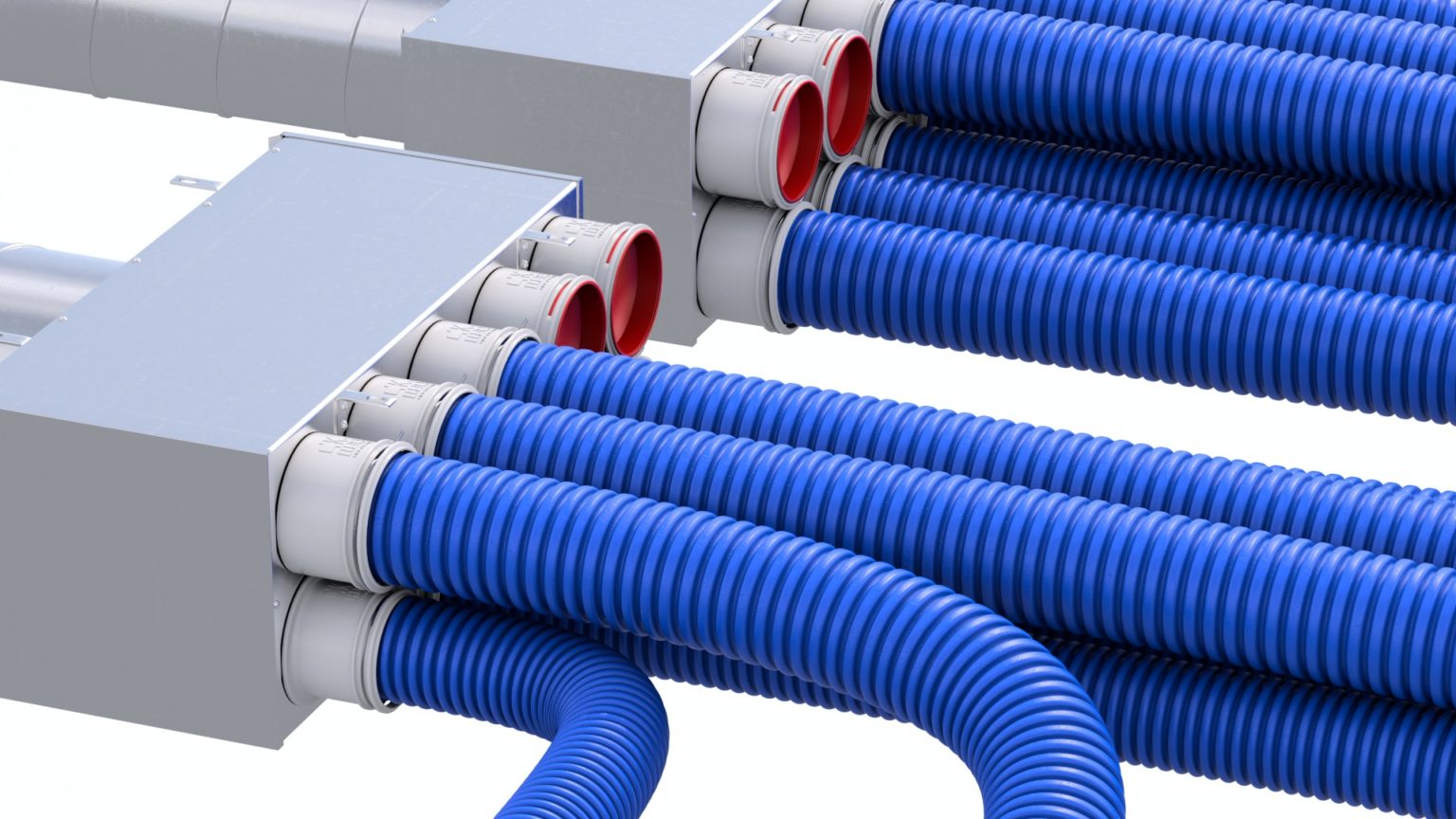

4. Fast and Airtight Installation

Installing a flexible duct system is like assembling a "Lego" set. There is no need to cut metal, use rivets, or tape to seal joints. The ducts simply click into the manifolds and are locked in place, while rubber gaskets ensure the highest airtightness class. This eliminates the risk of human error and ensures no air is lost on the way to the rooms.

Comparison Table: Spiro vs. REC Flex

| Feature | Galvanized (Spiro) Ducts | Flexible (REC Flex) Ducts |

|---|---|---|

| Acoustics | High risk of crosstalk, silencers required. | Excellent. No sound transmission between rooms. |

| Hygiene | Accumulates dust, corners are hard to clean. | Superior. Antistatic and antibacterial interior, easy to clean. |

| Installation Space | Requires significant ceiling space. | Compact. Fits in floors, walls, and low ceilings. |

| Cost | Cheaper materials, but expensive and slow installation. | More expensive materials, but cheap and extremely fast installation. |

Conclusion

If you are installing a ventilation system in a warehouse or factory, galvanized ducts are still a good choice. However, for a private house or apartment, the flexible duct system is the undisputed leader.

It guarantees what matters most in a home: silence, clean air without dust accumulation, and an aesthetic interior without the need to significantly lower ceilings.

Looking for a reliable solution? We recommend choosing the time-tested and certified REC Flex System. It is a complete system with high-quality HDPEA ducts, manifolds, and all necessary accessories, which you can easily install yourself or with the help of professionals.